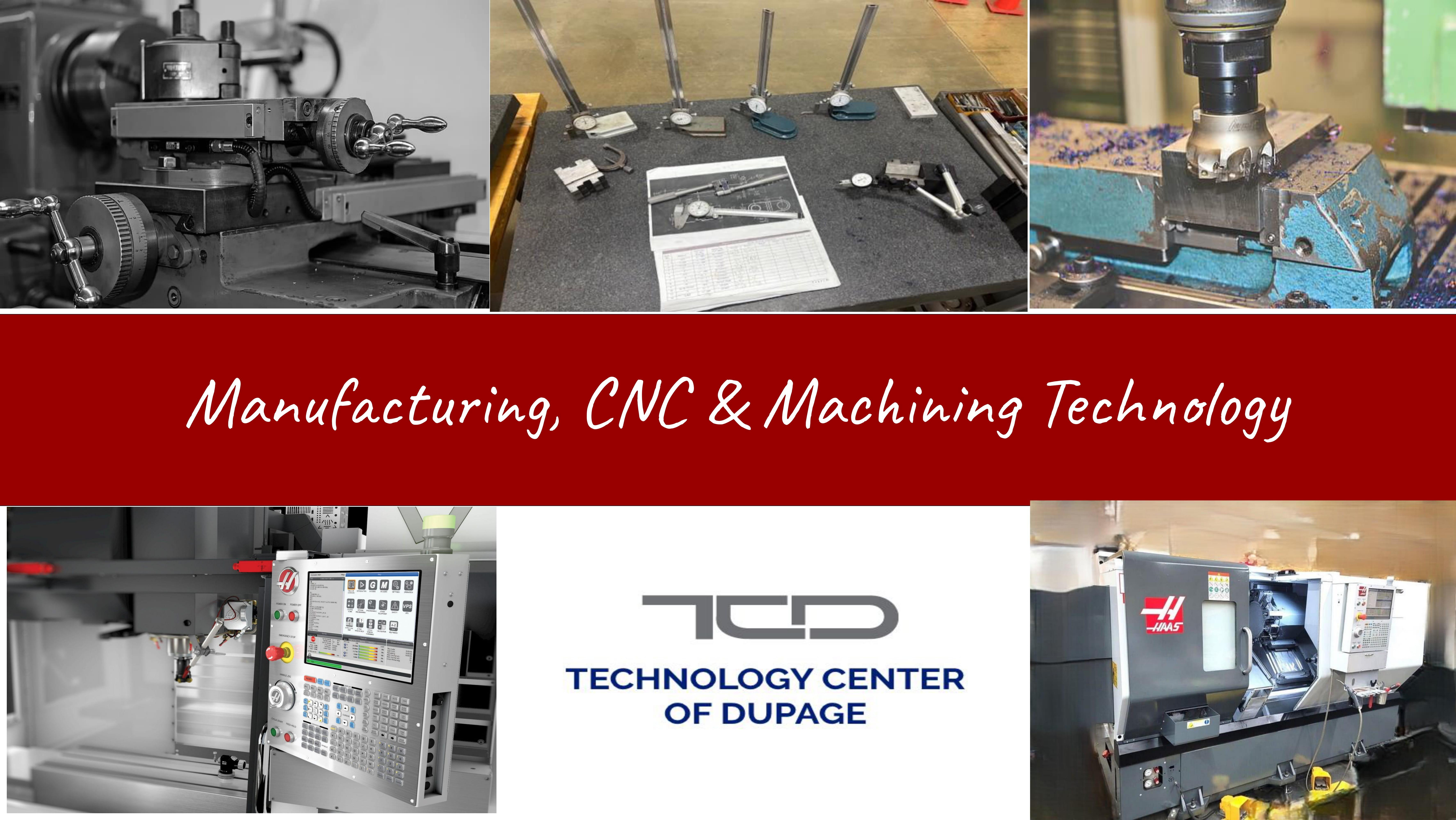

Manufacturing, CNC & Machining Technology

CNC Manufacturing Program: Building the Future of Advanced Manufacturing.

The CNC Manufacturing Program prepares students for the future of precision manufacturing by combining hands-on training, advanced technology, and industry-aligned practices. Our program is designed to equip students with the technical skills, problem-solving abilities, and professional mindset needed to succeed in today’s and tomorrow’s manufacturing workforce.

What the CNC Class Looks Like

Students learn in a modern, lab-based environment that mirrors real-world manufacturing settings. Instruction blends classroom theory with extensive hands-on practice, allowing students to move confidently from manual machining fundamentals to advanced CNC operations. Collaboration, safety, precision, and continuous improvement are emphasized throughout the program.

Tools & Software

Students gain experience with industry-standard tools and software, including:

- Metrology Tools: Calipers, micrometers, height gauges, and inspection equipment to ensure accuracy and quality

- Autodesk Inventor: 3D modeling and design for part development and manufacturing planning

- Mastercam: CNC programming software used to create, simulate, and optimize toolpaths

Equipment & Machinery

The program offers hands-on training with both manual and CNC equipment, including:

Manual Machines

-

-

- Bridgeport Milling Machines

- LeBlond Engine Lathes

- Manual Surface Grinders

-

CNC Machines

-

-

- Haas CNC Milling Machines

- Haas CNC Lathes

-

This combination ensures students understand machining fundamentals while mastering modern automated manufacturing processes.

Purpose of the CNC Program

The goal of the CNC Manufacturing Program is to develop skilled, work-ready technicians who can:

- Interpret technical drawings and specifications

- Set up, operate, and program CNC machines

- Apply precision measurement and quality control methods

- Use CAD/CAM software to design and manufacture parts

- Adapt to new technologies shaping the future of manufacturing

Student Success & Career Readiness

Student success is at the core of the program. Graduates leave with:

- Strong technical and hands-on machining skills

- Experience with industry-recognized equipment and software

- A foundation for internships, apprenticeships, employment, or continued education

- Professional skills such as teamwork, communication, and problem-solving

Our CNC Manufacturing Program empowers students to become confident, capable professionals ready to contribute to the evolving world of advanced manufacturing.

Instructor: Ricardo Marin Garcia

Student Services Assistant: Christian Rosales